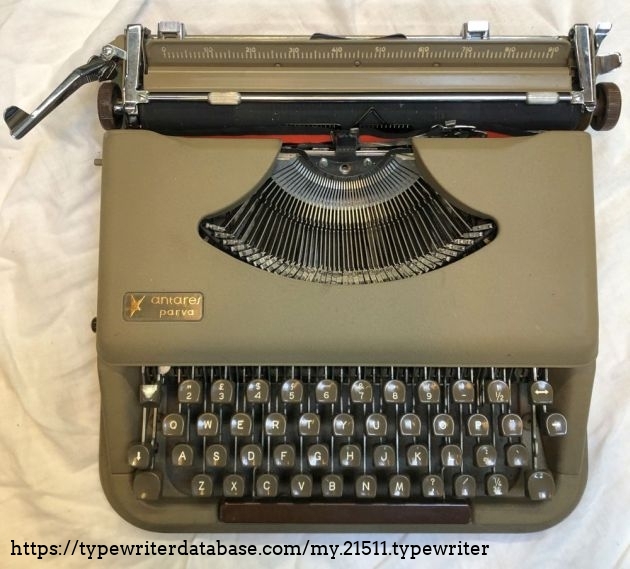

This machine has the looks of a Hermes. It looks great. Sleek, portable, a metal cover? No, the cover material in not a metal, it is some kind of thermoduric plastic. The cover is unlocked by pressing buttons on the sides.

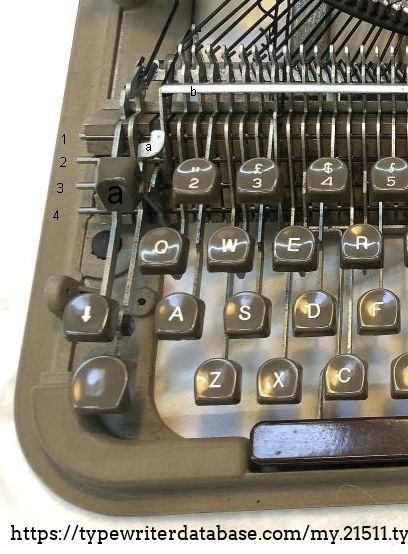

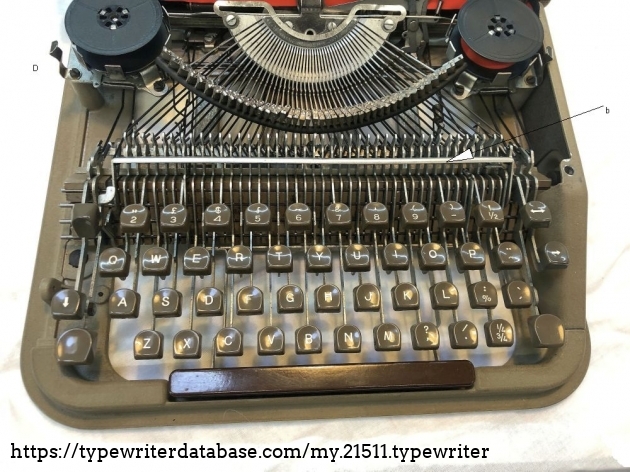

The keyboard has 42 keys, no key for ‘one’ and ‘zero’. Each bank of keys has its own pivot wire running from left to right. The keys all operate the types directly via a single pulling wire. This is a very simple design. Nonetheless, or because of that, the typing action is heavy.

The carriage pivots around an axis in the back of the machine, the caps key turns the carriage upward for typing capitals. There is no easy way to adjust up or down position.

The machine cover is an aluminium casting, as is the chassis. The side panels and bottom cover are aluminium pressings and stampings. The machine’s weight is 4390 grams

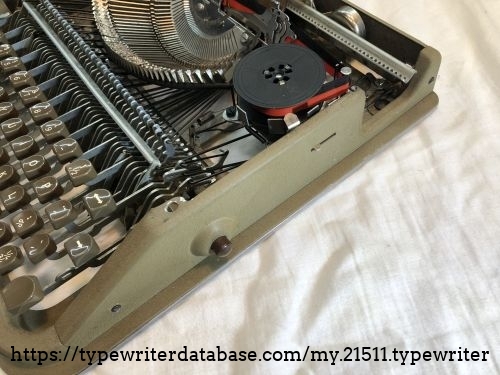

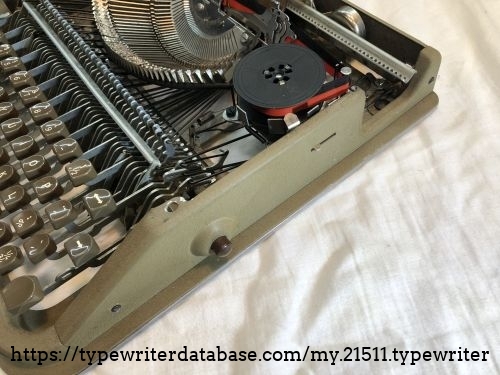

There are no ribbon-spool brakes and the auto-reverse levers on this machine do not work.

See the photos in the gallery for further details.

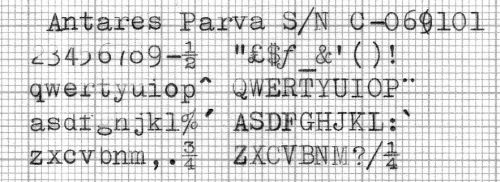

The typeface specimen shows that there were problems in type height. Also, the ribbon hopper does not always reach its upmost position. The flimsy hopper arm tends to get stuck in the small space between the type-guide and the flimsy target/ruler tin. Some bending and stretching has solved the problem.

Cost reduction has been the primary design objective in this Parva

The emblem

top cover with strap

The top cover is moulded from a thermoduric plastic and it is rather heavy, with 720 grams.

For comparison, the lid of a Hermes Baby of 1956 (two buttons on top) weighs 410 grams, that of a 1967 Baby (carrying strap and steel locking mechanism) is 590 grams.

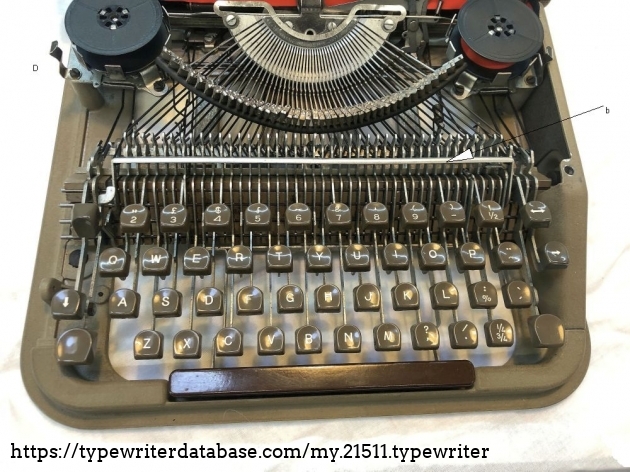

top view, no bonnet, one side wing removed

If you press any key, bar b comes towards you. Bar b (via an intermediate bar) actives the ribbon hopper for all keys and the ribbon advance mechanism at the first part of its stroke. At the end of a key stroke, bar b triggeres the escapement by one space, except for two keys at the right side of the keyboard. See a later picture.

The keys are grouped in four banks. At the top end of the key-levers, 42 steel wires are hooked in and springs are hooked on to pull the keys up after you pressed them down. The steel wires are linked directly to the type-arms.

In the upper left corner you will find one of two leaf springs. They hold the cover (bonnet, hood) down.

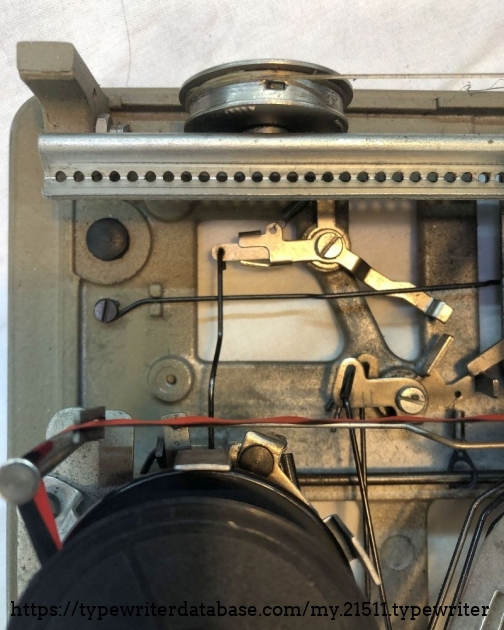

The bottom plate, in aluminium, together with a silencing felt. Assembly to the chassis by four M3 screws. Rubber feet protrude through the cover, easy assembly of the feet in the alu frame, no screws no nothing.

After removing the bottom plate, a view on the frame or chassis casting. The serial number is visible.

Zoomed in on the bearing bar carrier, you see (from to right) four steel bars that serve as pivot for all keys.

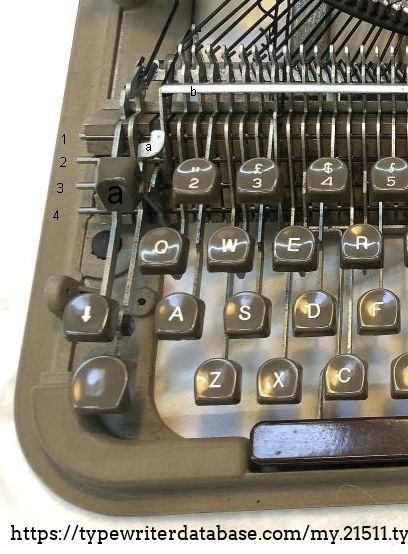

From left to right, you see the caps lock button, the caps key and a button ‘a’. This button is not to be pressed downward, but to be pushed away from you so that it pushed bar b away from you. This bar b in turns pushes home any key(-s) that might be stuck halfway. This is a Hermes Ambassador-like feature. In this machine, however, you rather push the whole machine away from you over your desk before two entangled keys come loose.

Top view detail right

Left to right you see

-1 is the backspace key

-2 is the cap key, with a slot to allow for the left hand caps key to be pressed in dependently

-3 is the End Of Line release key

- the white dotted key is one of two keys that do trigger the ribbon advance but do not trigger the escapement for a space. Hence the cut-out in these two keys that the other keys lack.

-sp is the right hand bearing of the space bar, with a return spring

-k is the right side rod that couples the bar b to a bar with a square section, further down in the machine. There is a similar rod at the left side, ensuring that the square bar does exactly what bar b does.

-the spring in the upper right corner pulls the ribbon hopper up against its stop at any key action

Detail upper left corner

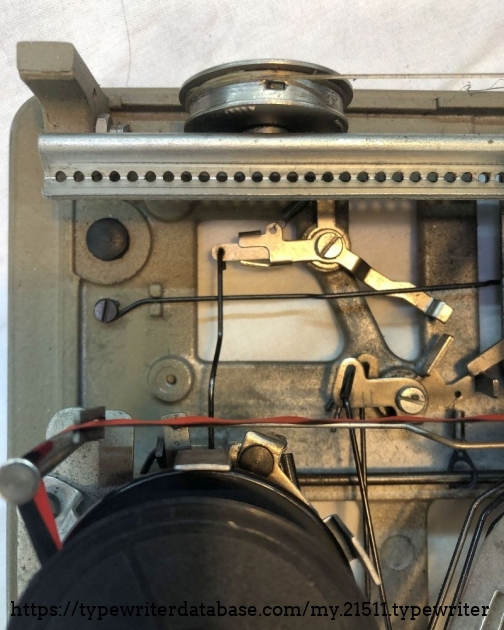

When pressing the space bar and any active key, the lever D turns anticlockwise and the escapement is activated and advanced the carriage one space.

Eight 8 spaces after the sound of the ‘end of line’ bell, the lever A turns clockwise, blocking lever A. Also, bar AB pushes up and limits the stroke of bar b from the earlier picture. This prevents any key to be used. Pressing the EOL release-key allows you to continue typing. Then, at the actual end of the carriage stroke, the lever A is activated again, now for good.

The bar C is acting as spring. It pushes the carriage upwards all the time. It compensated for part of the carriage weight, By doing so it make the effort of lifting the carriage more comfortable for the caps-key.

Also visible, although bearely: the ribbon threaded trough the forked stand that should change the ribbon transport direction at the 'end of tape'. It does not work.

Top cover, inside view

Clearly an alu casting

This photo shows the quirky leaf spring on the segment. Every type arm will meet it when trying to reach the paper. The spring helps any type arm to return to its backrest, even if it scratches the surface of the guidepost.

The types will make a good imprint hitting the keys hard, giving the type-arms a momentum to overcome this springs counterforce.

The colour selector is on the actual hopper arm. The selector itself can be decoupled and rotated by pushing it down, moving it to the left (red) or to idle (right) and releasing it.

The hopper is activated via a lever in the next picture.

Hopper activating lever, either by ‘any key’ of by outer most right side keys ^ and ‘

an overview of the right side

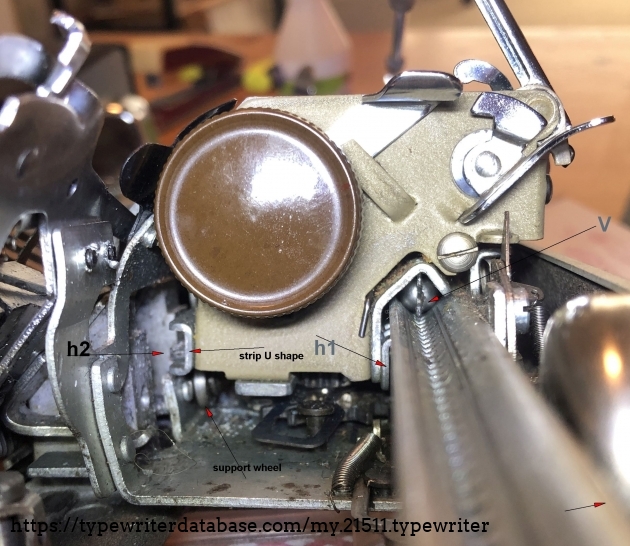

A typewriter carriage is usually guided between two linear bearings. The carriage can only move side-ways.

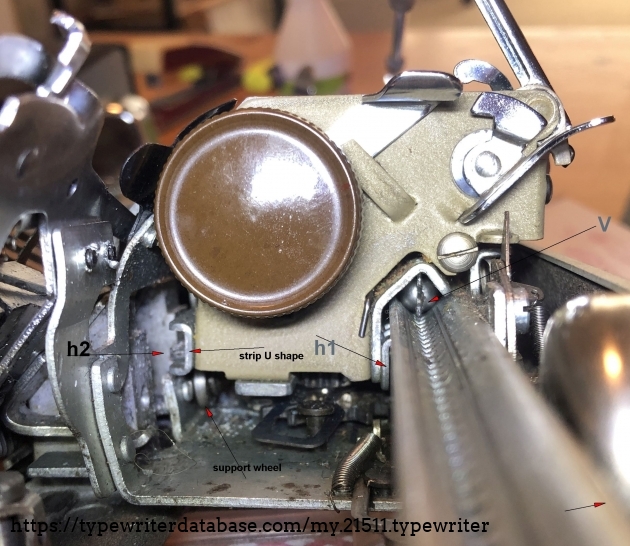

The Parva has merely one such linear bearing, at V. A single bearing can only carry a load in the downward direction. A simple hooks h1 prevents the bearing from falling apart and lose its balls if you would lift up the machine by its carriage.

A second support is required to prevent anticlockwise rotation of the carriage. A steel straight edge (called strip U shape) is bolted to the carriage. A single miniature wheel is attached to the chassis in the middle of the machine (with a small ball bearing) Rotation of the carriage is now prevented by having the U-strip running over that wheel. And again, only its own weight will ‘force’ the carriage to run over the wheel. To prevent that you lift the carriage of the machine, there is a second hook that reaches into the U, thus preventing motion in the vertical direction upwards. Facit have a similar design principle, in a much, much more refined execution.

The design shows that cost reduction has been a primary design goal.

The tension spring at the lower right seems to have been added after the design phase: this is no adequate way of mounting a spring.

Status: Typewriter Hunter

Points: 1007

As a retired product development engineer, I am fascinated by the design of electro-mechanical products in which parts move, make noise and, preferably, radiate a little heat. Most preferred are products that are operated by keys, like typewriters, accordeons and pianos.

My genetics and statistics on lifetime expectancy suggest that it is time for me to let you know about the fantastic design, product engineering and manuacturing skills of the generation before mine. I salute mr. Munk for the opportunity that he has created for me to show it to the world. Okay, a bit bombastic.

Comments? Email me at hreinder1950@gmail.com